The hardware system

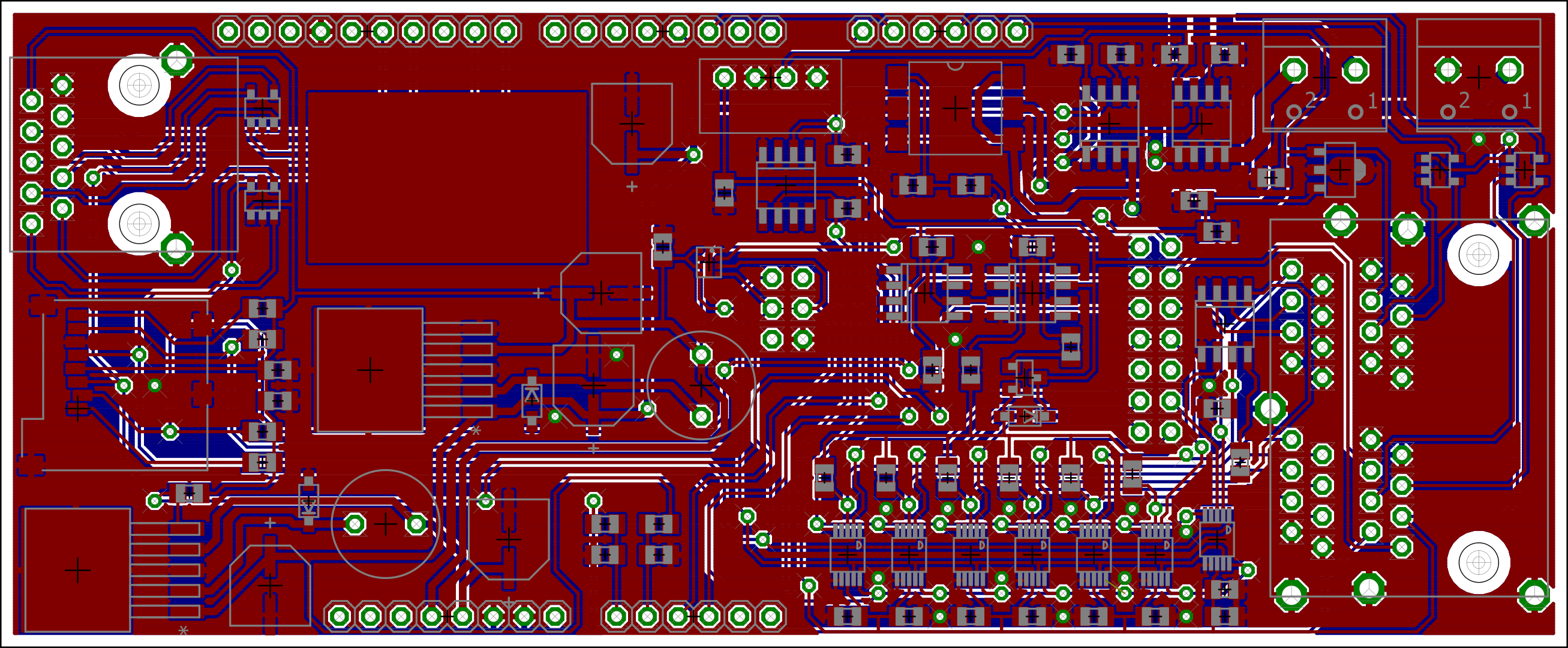

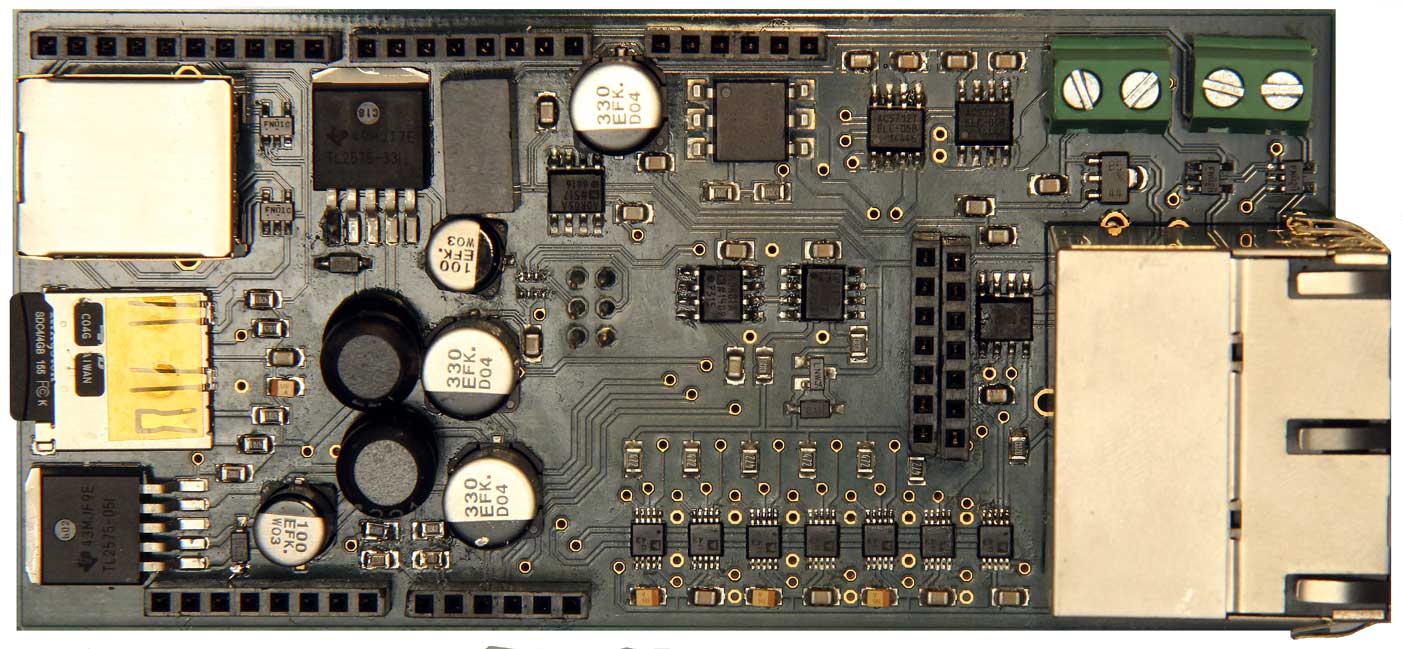

After we revised the circuit diagram and the layout of the PCB, two prototypes were produced in September. The boards were ordered by an external company and manually assembled by us with nearly 90 parts and over 400 soldering joints. The SMD parts were reflow soldered. First, the solder paste was dabbed on the pads of the board and then it was populated. After all, the whole PCB with the components sticking on it was heated till the solder paste melted. The through-hole components were soldered with a soldering iron, what needs to be done in this way later as well, because in the regular soldering process, the wave soldering, too much solder would be deposited at the pins, which must fit into the Arduino. The SMD parts will be assembled later by a pick-and-place machine.

One of the two prototypes is in use at the Umweltstation Würzburg right now.

(jg) 2015-11-29